Micropile Applications:

- Supporting New Loads in Congested Areas

- Seismic Retrofit

- Arresting Structural Settlement

- Resisting Uplift/Dynamic Loads

- Underpinning

- Excavation Support in Confined Areas

- Reticulated Pile Wall

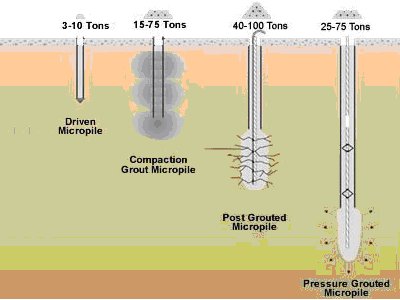

Types of Micropiles

- Pushed or Driven

- Compaction Grouted

- Post Grouted

- Pressure Grouted

Important Micropile Parameters

- Soil characteristics at pile shaft/soil

- interface Rock at pile tip

Benefits of Micropiles

- High-performance

- Design loads from 3 to 100+ tons

- Can be readily designed for tension/uplift loads

- Appropriate for a wide range of ground conditions

- Suitable for low headroom and restricted access

- Low noise and vibration

- Can penetrate obstacles

Micropile Design Steps

- Geotechnical study

- Determine load to be supported

- Design pile-to-structure connection

- Design pile-to-soil or rock load transfer

- Develop a pile testing program

Micropile Quality Control

Test selected piles to two times the static design load using standard ASTMD113 pile load test criteria

Typical Micropile Programs Involve

- Drilling holes, 2 inch to 12 inch diameter

- The construction of a pile shaft consisting of structural steel pipes, grout, steel sections and/or placement of reinforcing steel, as required by design

- The filling of the hole with high-strength cement grout

No comments:

Post a Comment