INTRODUCTION

The

use of bamboo as reinforcement in Portland cement concrete has been

studied extensively by Clemson Agricultural College. Bamboo has been

used as a construction material in certain areas for centuries, but its

application as reinforcement in concrete had received little attention

until the Clemson study.

A study of the

feasibility of using bamboo as the reinforcing material in precast

concrete elements was conducted at the U. S. Army Engineer Waterways

Experiment Station in 1964. Ultimate strength design procedures,

modified to take into account the characteristics of the bamboo

reinforcement were used to estimate the ultimate load carrying capacity

of the precast concrete elements with bamboo reinforcing.

Bamboo

was given recent consideration for use as reinforcement in soil-cement

pavement slabs in which the slabs behave in elastically even under light

loads. For this case ultimate load analysis was shown to be more

economical and suitable for use.

The results of

these investigations form the basis of the conclusions and

recommendations presented in this report. Further studies will be

required before complete confidence can be placed theoretical designs

based on the material presented here.

2. SELECTION AND PREPARATION OF BAMBOO

2.1 Selection

The following factors should be considered in the selection of bamboo culms (whole plants) for use as reinforcement in concrete structures:1. Use only bamboo showing a pronounced brown color. This will insure that the plant is at least three years old.

2. Select the longest large diameter culms available.

3. Do not use whole culms of green, unseasoned bamboo.

4. Avoid bamboo cut in spring or early summer. These culms are generally weaker due to increased fiber moisture content.

2.2 Preparation

Sizing.

Splints (split culms) are generally more desirable than whole culms as

reinforcement. Larger culms should be split into splints approximately ¾

inch wide. Whole culms less than ¾ inch in diameter can be used without

splitting. (See Fig 4)

Splitting the bamboo can

he done by separating the base with a sharp knife and then pulling a

dulled blade through the culm. The dull blade will force the stem to

split open; this is more desirable than cutting the bamboo since

splitting will result in continuous fibers and a nearly straight

section. Table II shows the approximate net area provided by whole culms

and by ¾-inch-wide splints, as well as the cross-sectional properties

of standard deformed steel bars and wire mesh.

Seasoning. When

possible, the bamboo should be cut and allowed to dry and season for

three to four weeks before using. The culms must be supported at regular

spacings to reduce warping.

Bending. Bamboo can

be permanently bent if heat, either dry or wet, is applied while

applying pressure. This procedure can be used for forming splints into

C-shaped stirrups and for putting hooks on reinforcement for additional

anchorage.

Waterproof Coatings. When seasoned

bamboo, either split or whole, is used as reinforcement, it should

receive a waterproof coating to reduce swelling when in contact with

concrete. Without some type of coating, bamboo will swell before the

concrete has developed sufficient strength to prevent cracking and the

member may be damaged, especially if more than 4 percent bamboo is used.

The type of coating will depend on the materials available. A brush

coat or dip coat of asphalt emulsion is preferable. Native latex, coal

tar, paint, dilute varnish, and water-glass (sodium silicate) are other

suitable coatings. In any case, only a thin coating should be applied; a

thick coating will lubricate the surface and weaken the bond with the

concrete.

3. CONSTRUCTION PRINCIPLES

In

general, techniques used in conventional reinforced concrete

construction need not be changed when bamboo is to be used for

reinforcement.

3.1 Concrete Mix Proportions

The

same mix designs can be used as would normally be used with steel

reinforced concrete. Concrete slump should be as low as workability will

allow. Excess water causes swelling of the bamboo. High early-strength

cement is preferred to minimize cracks caused by swelling of bamboo when

seasoned bamboo cannot be waterproofed.

3.2 Placement of bamboo

Bamboo

reinforcement should not be placed less than 1½ inches from the face of

the concrete surface. When using whole culms, the top and bottom of the

stems should be alternated in every row and the nodes or collars,

should be staggered. This will insure a fairly uniform cross section of

the bamboo throughout the length of the member, and the wedging effect

obtained at the nodes will materially increase the bond between concrete

and bamboo.

The clear spacing between bamboo

rods or splints should not be less than the maximum size aggregate plus ¼

inch. Reinforcement should be evenly spaced and lashed together on

short sticks placed at right angles to the main reinforcement. When more

than one layer is required, the layers should also be tied together.

Ties should preferably be made with wire in important members. For

secondary members, ties can be made with vegetation strips.

Bamboo

must be securely tied down before placing the concrete. It should be

fixed at regular intervals of 3 to 4 feet to prevent it from floating up

in the concrete during placement and vibration. In flexural members

continuous, one-half to two-thirds of the bottom longitudinal

reinforcement should be bent up near the supports. This is especially

recommended in members continuous over several supports. Additional

diagonal tension reinforcement in the form of stirrups must be used near

the supports. The vertical stirrups can be made from wire or packing

case straps when available; they can also be improvised from split

sections of bamboo bent into U-shape, and tied securely to both bottom

longitudinal reinforcement and bent-up reinforcement. Spacing of the

stirrups should not exceed 6 inches.

3.3 Anchorage and Splicing of Reinforcements

Dowels

in the footings for column and wall reinforcement should be imbedded in

the concrete to such a depth that the bond between bamboo and concrete

will resist the allowable tensile force in the dowel. This imbedded

depth is approximately 10 times the diameter of whole culms or 25 times

the thickness of ¾ inch wide splints. In many cases the footings will

not be this deep; therefore, the dowels will have to be bent into an

L-shape. These dowels should be either hooked around the footing

reinforcement or tied securely to the reinforcement to insure complete

anchorage. The dowels should extend above the footings and be cut so

that not more than 30 percent of the splices will occur at the same

height. All such splices should be overlapped at least 25 inches and be

well tied.

Splicing reinforcement in any member

should be overlapped at least 25 inches. Splices should never occur in

highly stressed areas and in no case should more than 30 percent of the

reinforcement be spliced in any one location.

4. DESIGN PRINCIPLES

Bamboo

reinforced concrete design is similar to steel reinforcing design.

Bamboo reinforcement can be assumed to have the following mechanical

properties:

When

design handbooks are available for steel reinforced concrete, the

equations and design procedures can be used to design bamboo reinforced

concrete if the above mechanical properties are substituted for the

reinforcement.

Due to the low modulus of

elasticity of bamboo, flexural members will nearly always develop some

cracking under normal service loads. If cracking cannot be tolerated,

steel reinforced designs or designs based on unreinforced sections are

required.

Experience has shown that split bamboo

performs better than whole culms when used as reinforcing. Better bond

develops between bamboo and concrete when the reinforcement is-split in

addition to providing more compact reinforcement layers. Large-diameter

culms split into ¾-inch-wide splints are recommended. (References to

splints in the following examples will be understood as meaning

¾-inch-wide splints of a specified thickness unless otherwise stated.

Design

principles for the more common structural members are presented in the

following sections. Examples of the use of these principles for each

member discussed are included.

4.1 Beams and Girders

Flexural

members reinforced with bamboo can be designed with the use of Figure

1. Bamboo longitudinal reinforcement should be between 3 and 4 percent

of the concrete cross section.

Figure 2 can be

used to convert existing designs for steel reinforced beams to

equivalent bamboo reinforced designs. The curve provides the

cross-sectional dimensions of a bamboo reinforced beam that will have

the same bending moment resistance coefficient as a balanced steel

reinforced beam, singly reinforced. Economy of concrete increases going

to the left on the curve; therefore, deeper, narrower replacement beams

are recommended.

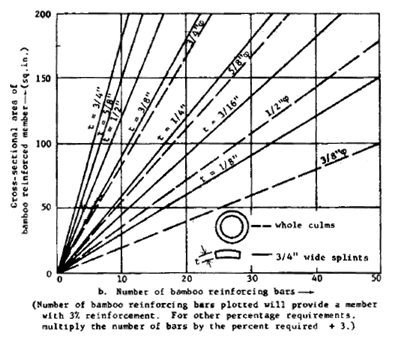

The number and size of bamboo

reinforcing rods (culms or splints) can be selected from Figure 2b.

These curves are drawn for 3 percent of the concrete cross section as

bamboo reinforcement which is in the optimum range for flexural members.

Other reinforcement percentages can be used as noted on the figure. A

minimum number of rods should be used to provide adequate spacing. The

bamboo stirrup area should always be about 4 times the steel stirrup

area.

4.1.1 Example 1 - Design of Bamboo Reinforced Beam:

Design

a bamboo reinforced concrete beam to span 8 feet and to carry a uniform

dead load plus live load of 500 pounds per linear foot and two

concentrated loads of 12,000 pounds each symmetrically located 2 feet

each side of the center line of span. Assume the ultimate strength of

the concrete is 2500 psi; the allowable compression stress is 0.45 f'c or 1125 psi. Allowable unit diagonal tension stress, , in the concrete is 0.03 f'c

or 75 psi. Allowable tension stress, s, in the bamboo is 4000 psi; the

allowable unit bond stress between bamboo and concrete is 50 psi.

1. At the intersection of the allowable stress curves (Figure 1) for concrete and bamboo, find R = 115 and p = 3.1 percent. 2. Maximum bending moment, M, is given by:

M = [500(8)2(12)]/8 + 12,000(2)(12) = 336,000in. - lb.

R = M/bd2

3. From

bd2 = 336,000/115 = 2920 in.3

4. If b = 8 in. is chosen, then d = (2920/8)½ = 19.1 in.

5. Bamboo reinforcement = pbd = 0.031(8)(19.1) = 4.75 sq in.

6. Use ¾-inch-thick splints, area = 0.563 sq in. (from Table II). Number required = 4.75/0.563 = 8.4; round up to 9. Space evenly in three rows. Bend up top row randomly in the outer one-third ends of the beam.

7. Check the bond stress. Maximum shear at the support, V, is determined as:

V = 500(8)/2 + 12,000 = 14,000 lb.

The perimeter of one splint is 4(3/4) or 3 in.; the total perimeter of the longitudinal reinforcement, ∑0,

is 9(3) = 27 in. The value of j = 0.925 is taken from Figure 1 for 3.1

percent reinforcement. The bond stress, u, is calculated from:

u = V ÷ ∑ojd = 4,000 ÷ 27(0.925)(19.1) = 29 psiThis is less than the allowable bond stress of 50 psi.

8. Calculate the shear, V', taken by the concrete from

V' = νbjd = 75(8)(0.925)(19.1) = 10,600 lb.

Where ν is the allowable diagonal tension stress of the concrete.

9. Try ¼-inch-thick splints for stirrups. The area provided by one stirrup bent into a U-shape, A, is 2(0.1875) = 0.375 sq. in. Maximum spacing, s, is given by:

s = Aσjd ÷ (V - V') = 0.375(4,000)(0.925)(19.1) ÷ (14,000 - 10,600) = 7.8in.

Common practice is to include two additional stirrups past the point where diagonal tension reinforcement is not needed.

Example 2 - Replacement of a Steel Reinforced Beam with a Bamboo Reinforced Beam:

Construction drawings call for the beam given in the sketch below. Replace it with a bamboo reinforced beam. There are no objections to deepening the member.

1. Select the cross-sectional dimensions from Figure 2a. Avoid using sections with depth to width ratios greater than 4 for reasons of stability. Try width of 1.0b or 10 in. and a depth of 1.32d or 29.0 in. The area is 290 sq in.

2. The amount of reinforcement can be selected from Figure 2b. Assume that 3/4-inch-thick splints will be used. The number of splints required for 200 sq in. is determined at 11. This number is multiplied by the ratio 290/200 to get 16 splints. These should be-distributed evenly in four rows.

3. Determine the vertical stirrups required. The No. 4 steel stirrups have a cross-sectional area of 0.2 sq in. (Table II). These stirrups are spaced at 10 in. which provides (12/10)(0.2)= 0.24 sq in. of reinforcement in a 12-inch length. Four times this area should be used for bamboo stirrups or 0.96 sq in. per foot of length. From Figure 4, select 3/8-inch-thick splints spaced at 4-inch centers.

4. The top two rows should be bent up randomly in the outer one-third sections of the beams to assist the vertical stirrups in resisting diagonal tension.

The final design is shown in the following sketch.

Columns

Bamboo

reinforcement in columns serves to resist a compression load equal to

that taken by the concrete it displaces; it also will resist shear and

tensile stresses. Of the full cross section of concrete, only 80 percent

is considered effective in rectangular tied, columns. Allowable

concrete stress should not exceed 0.225 f'c where f'c is the ultimate compressive strength of the concrete.

Vertical

reinforcement should be approximately 4 percent of the column cross

section for rectangular columns. When bamboo is used as lateral tie

reinforcement, the ties should be spaced not over 16 times the least

dimension of the vertical reinforcement nor farther apart than the least

dimension of the column. Enough ties should be provided so that every

vertical bar is held firmly in its designed position and has lateral

support equivalent to that provided by a 90-degree corner of a tie. A

common rule for determining the size of a tie is that its

cross-sectional area is 2 percent of the area of all the vertical

reinforcement confined by it.

The concrete

cross-sectional area of bamboo reinforced rectangular columns

conservatively should be 2.25 times the concrete area of steel

reinforced rectangular columns, indicating a 50-percent increase in face

dimensions.

4.2.1 Example 3 - Square Bamboo Reinforced Column Design:

Determine the cross section and bamboo reinforcement of a column required to carry an axial load of 70,000 lb. Ultimate compression strength of the concrete, f'c, is 2500 psi.1. For an unreinforced rectangular column the safe axial load, P, is given by:

P = 0.8Ag (0.225 f'c)

where Ag is the cross-sectional area of the concrete column.

2. The column should have a cross-sectional area of:

Ag = 70,000 ÷ 0.8 (0.225) (2500) = 155.5 sq. in.

3. If a square column is chosen, it will have face dimensions of

b = (155.5)½ = 12.47 in., say 12.5 in.

4.

The amount of vertical reinforcement should be 4 percent of the

concrete area and can be obtained from Figure 2. Try ¾-inch-thick

splints. The number required is 8.8 for an area of (12.5)(12.5) = 156 sq

in. However, Figure 2 provides only 3-percent reinforcement; thus 8.8

should be multiplied by (4/3) to get 11.7. Thus, 12 splints should be

used; these should be spaced evenly around the perimeter with 1½ in. of

cover. Lateral ties should be arranged as shown in the following figure

to provide each vertical splint with a 90-degree corner (or smaller).

Example 4 - Replacement of Steel Reinforced Square Column Design with Bamboo Reinforced Square Column:

Construction drawings call for a 12-inch-square concrete column reinforced with 12 No. 6 steel reinforcing bars. Three No. 2 ties on 12-inch centers are required. Replace this column with a square column reinforced and tied with bamboo.1. The face dimensions should be increased by 50 percent. The bamboo reinforced column will have sides of 1.5(12) = 18.0 in.

2. The cross-sectional area is 18.0(18.0) = 324 sq in. Use 4 percent of the concrete area as vertical reinforcement. Figure 2 is used to determine the size and number of bamboo reinforcement. Assume 3/4-inch-thick splints will be used. For a concrete area of 200 sq in., the number of these splints required is 11.0. Since this figure provides 3-percent reinforcement, the number of splints should be multiplied by the ratio (4/3); it should also be multiplied by the ratio (324/200) as a correction factor for concrete area. These multiplications indicate that 24 splints should be used.

3. Lateral ties should be arranged as shown in the following figure. Tie reinforcement should be 2 percent of the area of the vertical bars confined by it. Each tie confines four 3/4-inch-thick splints; therefore, the calculations for tie size and spacing are identical to those in Example 3.

Ground-Supported Slabs

Figure

3 is used to determine slab thickness and required amount of bamboo

reinforcement. Figure 4 can be used to determine the size and spacing of

the reinforcement. In general, the reinforcement spacing should not be

greater than the slab thickness.

When designs

are available for steel reinforced slabs, no change in thickness is

required when reinforced with bamboo instead of steel. However, the

volume of the bamboo matting reinforcement should be about 4 times the

amount used for steel matting.

4.3.1 Example 5 - Ground-Supported Slab Design:

Design a bamboo reinforced concrete slab to support a maximum wheel load of 7000 pounds. The wheel contact area on the slab is estimated at 60 sq in. Slab length between joints will be 8 ft.1. The slab thickness is determined from Figure 3a to be about 5½ in.

2. The required reinforcement is determined from Figure 3b to be 0.11 sq in. per foot of slab width.

3.

The amount of the reinforcement is determined from Figure 4. The

required amount of reinforcement can be provided by 1/8-inch-thick

splints on 12-inch centers. However, in general, the reinforcing spacing

should not be greater than the slab thickness; a 6-inch spacing is

adequate.

4.3.2 Example 6 - Replacement of Steel Reinforced Slab with a Bamboo Reinforced Slab:

Construction drawings call for a 6-inch-thick slab reinforced with No. 10 gage steel reinforcing wire on 6-inch centers. Replace it with a bamboo reinforced slab.1. The thickness of the slab does not change.

2.

From Table II, the cross-sectional area of a No. 10 gauge wire is

0.0143 sq in. Since these wires are spaced at 6 in., the area per foot

is 0.0286 sq in. Bamboo reinforcement should be 4 times that of the

steel reinforcement or 0.114 sq in. per foot of slab width. From Figure

4, 1/8-inch-thick splints on 8-inch centers is adequate; however, the

spacing should not exceed the slab thickness so a 6- inch spacing should

be used.

4.4 Walls

Non-bearing

concrete walls should have a thickness of not less than 5 inches and not

less than 1/30 the distance between the supporting or enclosing

members; they should be reinforced with at least 3/4-inch-diameter culms

on 6-inch centers in both vertical and horizontal directions. This

reinforcement should be provided as a one-layer mat in the middle of the

wall. Two bamboo culms 1/2 inch or more in diameter should be placed

above and at the sides of openings, and two 3/4-inch-diameter culms 4

feet long should be placed diagonally across the corners of openings.

Figures and Tables

Figure 1.↑ Resistance coefficients for bamboo reinforced concrete beams and their flexural members.

Figure 2.↑ Bamboo substitute beams and reinforcement.

Figure 3.↑ Slab thickness and reinforcement for ground supported slabs.

Figure 4.↑ Size and spacing of bamboo reinforcement in slabs and walls.

Table II . Properties of bamboo and steel reinforcing bars

BAMBOO

| Whole Culms | |

| Diameter (in.) | Area (sq. in.) |

| 3/8 | 0.008 |

| 1/2 | 0.136 |

| 5/8 | 0.239 |

| 3/4 | 0.322 |

| 1 | 0.548 |

| 2 | 1.92 |

| 3/4 Inch Wide Splints | |

| Thickness (in.) | Area (sq. in.) |

| 1/8 | 0.094 |

| 1/4 | 0.188 |

| 3/8 | 0.282 |

| 1/2 | 0.375 |

| 3/4 | 0.5563 |

STEEL REINFORCING

| Nominal Dimensions - Round Sections |

|

Bar Designation No.

| Nominal Diameter (in.) | Cross Sectional Area (sq. in.) |

|

2

|

0.250 (2/8)

|

0.05

|

|

3

|

0.375 (3/8)

|

0.11

|

|

4

|

0.500 (4/8)

|

0.20

|

|

5

|

0.625

|

0.31

|

|

6

|

0.750

|

0.44

|

|

7

|

0.875

|

0.6

|

|

8

|

1.00

|

0.79

|

|

9

|

1.128

|

1.00

|

|

10

|

1.270

|

1.27

|

|

11

|

1.410

|

1.56

|

STEEL WIRE

| Wire size chart | |||

| AS&W Wire Gauge Numbers | Diameter (in.) | Area (sq. in.) | Weight (lb/ft) |

| 0000 | 0.3938 | 0.12180 (2/8) | 0.4136 |

| 000 | 0.3625 | 0.10321 | 0.3505 |

| 00 | 0.3310 | 0.086049 | 0.2922 |

| 0 | 0.3065 | 0.073782 | 0.2506 |

| 1 | 0.2830 | 0.062902 | 0.2136 |

| 2 | 0.2625 | 0.054119 | 0.1838 |

| 3 | 0.2437 | 0.046645 | 0.1584 |

| 4 | 0.2253 | 0.039867 | 0.1354 |

| 5 | 0.2070 | 0.033654 | 0.1143 |

| 6 | 0.1920 | 0.028953 | 0.09832 |

| 7 | 0.1770 | 0.024606 | 0.08356 |

| 8 | 0.1620 | 0.020612 | 0.07000 |

| 9 | 0.1483 | 0.017273 | 0.05866 |

| 10 | 0.1350 | 0.014314 | 0.04861 |

| 11 | 0.1205 | 0.011404 | 0.03873 |

| 12 | 0.1055 | 0.0087417 | 0.02969 |

| 13 | 0.0915 | 0.0065755 | 0.02233 |

| 14 | 0.0800 | 0.0050266 | 0.01707 |

| 15 | 0.0720 | 0.0040715 | 0.01383 |

| 16 | 0.0625 | 0.0030680 | 0.01042 |